Professional with products

Top Equipment is specialised in the development, production and installation of:

Top Equipment is specialised in the development, production and installation of:

- Air chilling systems and combined in-line air/water chilling systems

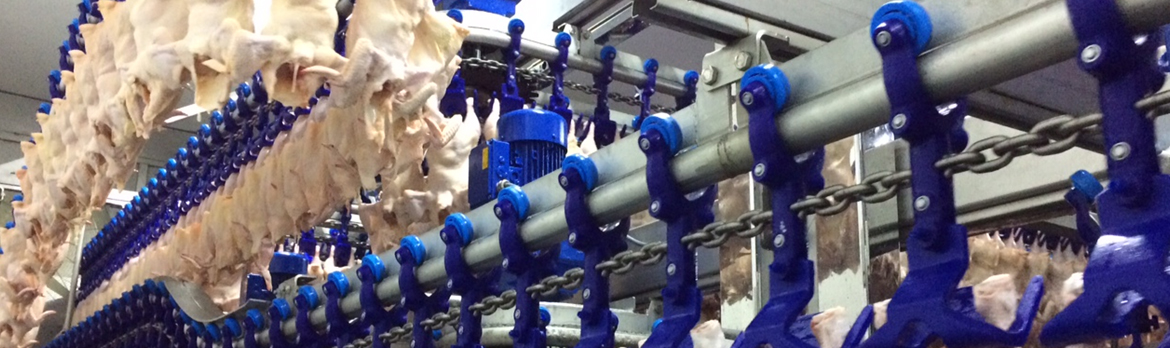

- Overhead conveyor transport systems

- Process equipment

- Stainless steel constructions

We construct these products for customers in the poultry and red meat industry. Read on for a brief overview of what we have to offer.

Combined in-line water chilling with air chilling systems

Our air chilling units prove their worth in numerous production lines around the world. If you want to expand your capacity or maximum efficiency of your chilling is required, you can choose the water chilling option. We integrate this water chilling with your air chilling system, and your production line immediately benefits from maximum chilling efficiency.

Combi Chilling System

Combination of chilling with water and air:

You want to guarantee the quality and shelf life of your fresh products to your customers. Therefore you must prevent the growth of bacteria throughout the entire processing cycle. After the slaughtering process, it is therefore important that you quickly, correctly and efficiently chill your products to below 4 °C.

Top Equipment and its team have developed the Combi Chilling System. The system consists of a sophisticated combination of water and air chilling. The first part consists of multiple tank sections filled with chilled clean water. This is interspersed with lines where the product is cooled. The total residence time of the product in the in-line tanks is about 4 minutes. At the beginning of the cooling process this results in a significant temperature drop. Chilling then continues in the remaining air-chilling process.

Optimum chilling and control

Top Equipment develops systems, made to order, entirely in stainless steel and non-corrosive materials. This tailored approach ensures that they perfectly fit the needs of your slaughterhouse. We create the air flow by maintaining a constant air temperature of around 0 °C and generating lateral air circulation in the chilling tunnel. This, in combination with the water tank sections, enables you to achieve optimum heat transfer. We select all the refrigeration components, such as compressors, air coolers and fans, specifically for you. We also provide optimum control and monitoring of the entire process.

In-line chilling of harvested chicken organs

We deliver our in-line air/water chilling systems not only for chilling the chicken meat but also for the in-line chilling of the organs. Top Equipment's specific chilling method results in a process that produces organs of excellent quality, with a long shelf life.

Serving the red meat industry

For the red meat industry Top Equipment designs, produces and installs highly innovative chillers specifically for organ meats. These in-line solutions are based on the same proven technique for cooling with air and water that Top Equipment employs in the poultry industry.

More information

Want to hear more? Do you have a question or would you like a no-obligation quote? Please feel free to contact us.

Watch more videos

H2H Euthanizer: quick, stress-free euthanasia of poultry with electricity

H2H Euthanizer: quick, stress-free euthanasia of poultry with electricity

Farmers with poultry barns are in great need of a method to euthanize irrecoverably sick, paralyzed or crippled poultry quickly, effectively and in a manner that is completely painless and stress-free for the animals.

Serving the red meat industry

Serving the red meat industry

For the red meat industry Top Equipment designs, produces and installs highly innovative chillers specifically for organ meats. These in-line solutions are based on the same proven technique for cooling with air and water that Top Equipment employs in the poultry industry.